Rail Equipment

World class Railway, workshop and depot equipment from a range of market leading suppliers

Sand Pump Systems

Newtek offers a comprehensive range of sand pumping solutions designed to provide efficient and reliable sand filling for various applications.

Stationary Sand Pumps:

These pneumatic sand pumps, developed by Newtek, are ideal for automatic loading to sandboxes on trams, locomotives, and trains. Featuring a capacity range of 90-800 L, these pumps are equipped with a movable arm and a specially designed gun to prevent sand loss and minimize environmental pollution. The innovative filtration system effectively captures residual dust during the filling process.

Newtek Ameda Moving Sand Pumps:

Newtek presents autonomous self-propelled vehicles designed specifically for sand filling. These vehicles feature a seat, cabin cover, wipers, and more. With a pressurized sand tank capacity of 200-1200 kg (approx.), flexible hose, and dispensing nozzle, they enable efficient loading of sandboxes on trains and trams. The sand transfer to the sandboxes is facilitated by compressed air generated by the compressor integrated into the vehicle. This fully autonomous system includes batteries and a power inverter. The dust control measures incorporated in the design ensure minimal dust production during sand filling.

Sand Silo 20m3 (30 Tons): Newtek’s sand silo is a versatile solution for sand storage. With its unique design, the silo eliminates the need for stairways and railings on the roof, simplifying maintenance. The cylindrical support structure features a flap and a locked door, ensuring safe filling with vent valves and a flow meter for precise measurement. The digital display indicates the sand level in percentage or kg cubed. For controlled extraction, a secured manual valve is provided. The silo also includes a ventilation filter with a 50 L tub for collecting fines, promoting clean operations. Its general measurements are Ø 2,250 x 7,500 mm high.

Choose Newtek’s advanced sand pumping solutions for efficient sand filling, superior performance, and enhanced safety in your operations.

Features:

Efficient and Reliable Sand Filling

Innovative Design and Durable Construction

Dust Control and Enhanced Safety Measures

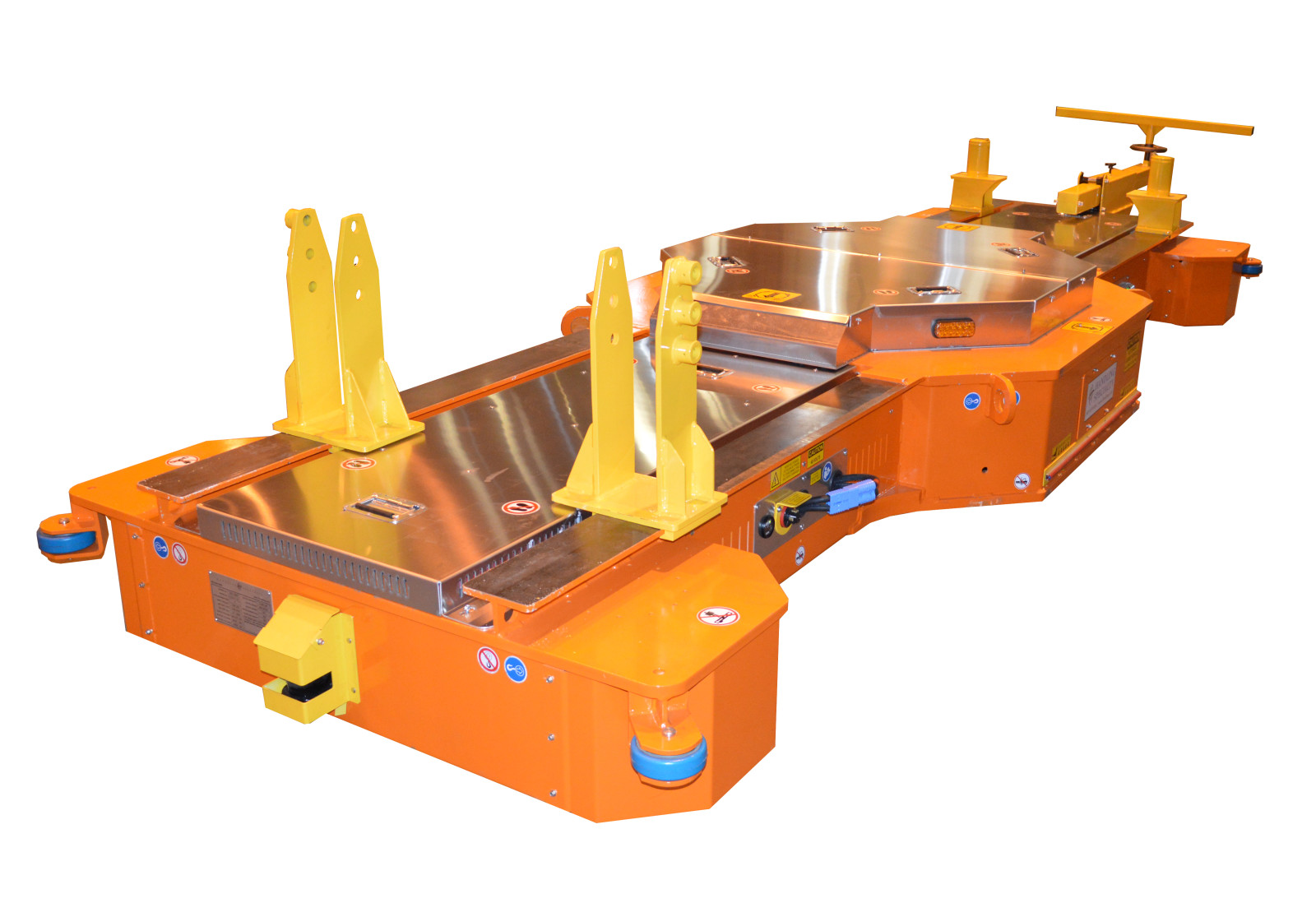

Automatically Guided Vehicles (AGVs)

Automatically Guided Vehicle systems are perfect for heavy-duty manoeuvring and overall automation of the factory floor. Looking for a custom, fully autonomous vehicle that moves and transports items in production, warehouse, and distribution centres without operator intervention or permanent conveying systems?

Our range of Handling Specialty vehicles include:

- AGV Roll-Over Vehicles (Energy)

- Automatic Guided Vehicles (Automotive)

- Transporter for Locomotive Transformer (Rail/Transportation)

- Self-Propelled Traversing Aerospace Parts Lift (Aerospace & Defence)

- Motorised Transport Cart for Defence Industry (Aeropace & Defence)

- AGC Automatic Guided Cart (Automotive)

- Self Propelling Lift for Steel Industry (Process Industries)

- Towline Cart for Motorcycle Assembly (Advanced Manufacturing)

Manually Guided Vehicles (MGVs)

Handling Specialty offer a wide range of Manually Guided Vehicles to suit the needs of many industries. Their selection is feature-rich and designed for the advanced manufacturing sector who are focused on continuous improvement. Additionaly, these cehicles can easily and cost-effectively be upgraded to an automated guided vehicle system. Automotive, rail and aerospace are just some of the industries which find countless uses for automated and manually guided vehicles.

This includes:

- Manually Guided Vehicles (Aerospace & Defence)

- 40 and 70 Ton Engine MGVs (Energy)

- MGV Roll-Over Vehicles (Energy)

- Automotive MGVs (Automotive)

- Manually Guided Rail Industy Vehicles (Rail/Transportation)

- Locomotive Manufacturing MGVs (Rail/Transportation)

- Manually-Automatically Guided Vehicle (Process Industries)

- Transporter for Locomotive Transformer (Rail/Transportation)

- MGV Engine Transporter for Aerospace Industy (Aerospace & Defence)

- Motorised Transport Cart for Defence Industry (Aerospace & Defence)

- Self-Propelling Lift for Steel Industry (Process Industries)

- Towline Cart for Motocycle Assembly (Advanced Manufacturing)

- Manually Guided Vehicle (Advanced Manufacturing)

Gen-Set Locomotives

Single and Dual LEAF Gen-Set Locomotives

The original Railserve LEAF is powered by a single Cummins QSX15-Tier 4 Compliant 600 hp GenSet engine. The proven track record of the Railserve LEAF in numerous switching operations makes this competitively priced locomotive an exceptional value for any rail yard.

The Dual LEAF has all of the proven features of the original LEAF, but with more pulling power. With two Cummins QSX15-T4 600 hp GenSets, it can achieve higher speeds and provides built-in backup power. The Dual LEAF is ideal for a combination of yard switching and longer haul rail movements.

Features

- Eliminates wet-stacking and uses 90% less oil

- Onboard computer provides real-time engine performance reporting

- Programmable maximum speed control

- Traction control system minimizes wheel slip

- 10% lower decibel output than conventional locomotives

- Programmable to shut down if not moved after a pre-set time limit

- One-button push-start eliminates up to 30 minutes of startup preparation

- Same cab controls as conventional locomotives

Features:

Lower fuel consumption by 45-72% over conventional locomotive

Reduce NOx emissions and particulate matter by up to 84%

Local factory-trained support available

LOK 7.90 E / 10.90 E / 13.90E

LOK 7.90 E, 10.90 E & 13.90 E: LOK-E Electric Shunt Vehicles

For heavy shunting tasks the 7.90, 10.90 and 13.90 E are up to the challenge. With drawbar pull up to 120kN, the LOK-E range is well suited to larger shunting operations or working in yards with steeper grades. Options for multiple batteries allow these vehicles to work for longer between charging.

These models of rail shunting equipment are currently utilised at various locations within Australia as shunt and vehicle placers, locomotive shunting and in lieu of progression systems. In addition, these models can be configured in any rail gauge within Australia whilst still maintaining the on and off tracking flexibility that a Rail/Road machine supplies.

Features:

Fully electric, no emissions

Great shunting performance

Local factory-trained support available

LOK 16.150E / 22.150 E

LOK 16.150E / 22.150 E: LOK-E Electric Shunt Vehicles

The LOK 16.150 E & 22.150E are the highest capacity rail-road electric battery-powered shunters.

With drawbar pull of up to 180 kN these electric shunters have the same capacity as the highest performing Diesel shunters.

The LOK 16.150 E & 22.150 E can enter and exit the tracks and move quickly from one part of the plant to another, reducing operating costs and making the railcar material handling activities more efficient. These models of rail shunting equipment are currently utilised at various locations within Australia as shunt and vehicle placers, locomotive shunting and in lieu of progression systems.

These models maintain their ability to on and off track as required in Standard Gauge and Broad Gauge configurations. In Narrow Gauge (1067mm) they are Rail only.

Features:

Fully electric, no emissions

Efficient on and off-track

Local factory-trained support available

Wheel Borer

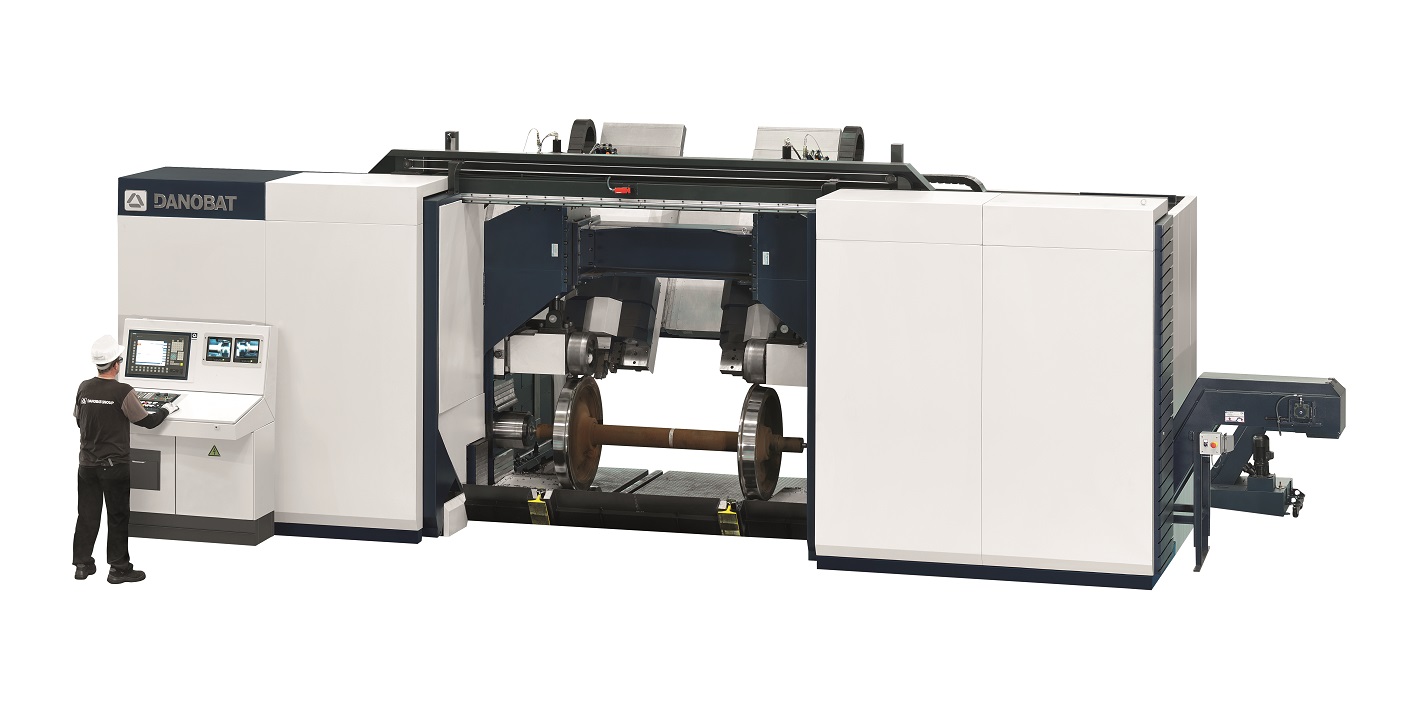

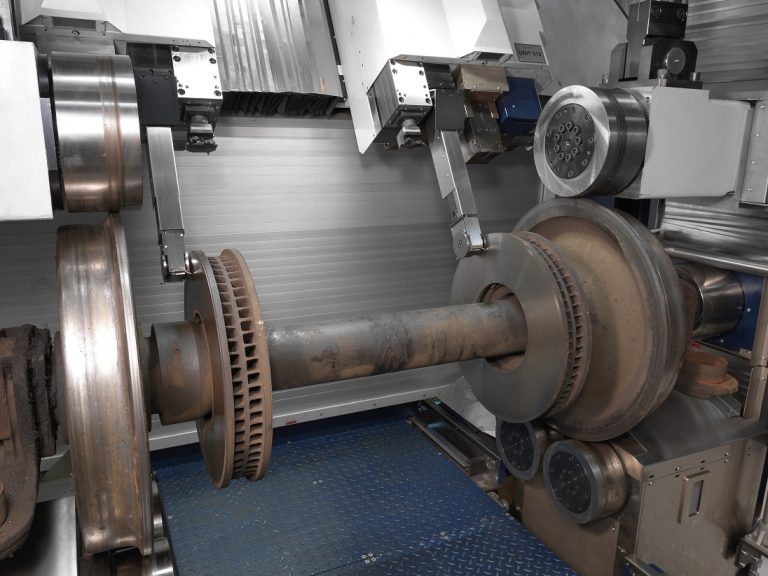

Wheel Borer: Danobat Wheel Shop Equipment

The DANOBAT MV Boring Machine offers high precision train wheel hub borings for railway maintenance and production workshops. These machines consist of a boring unit with vertical displacement and a fixed, non-rotary table where the railway wheel can be mounted.

Like all DANOBAT products their MV Boring Machine draws on a customised approach to ensure it delivers the highest quality results.

- Fixed table and rotating boring tool configuration

- Rigid column assembly with the rotary boring tool mounted on vertically guided headstock unit.

- Highly accurate boring bar

- Loading and unloading solutions depending on production requirements

Features:

Guarantees required machining tolerances

Allows full integration with measurement systems

Local factory trained support available

Body Supports

Body Supports: Whiting Lifting Equipment

Used in conjunction with Whiting body hoists, Whiting body supports have no motive power capability to raise and lower cars but provide support of the rolling stock body when bogies are being removed. Standard capacities range from 4.5 to 18 tonnes.

Features:

Suitable for under the car inspections

Great power capacity

Variable raise height

Repair in Place (RIP) Jacks

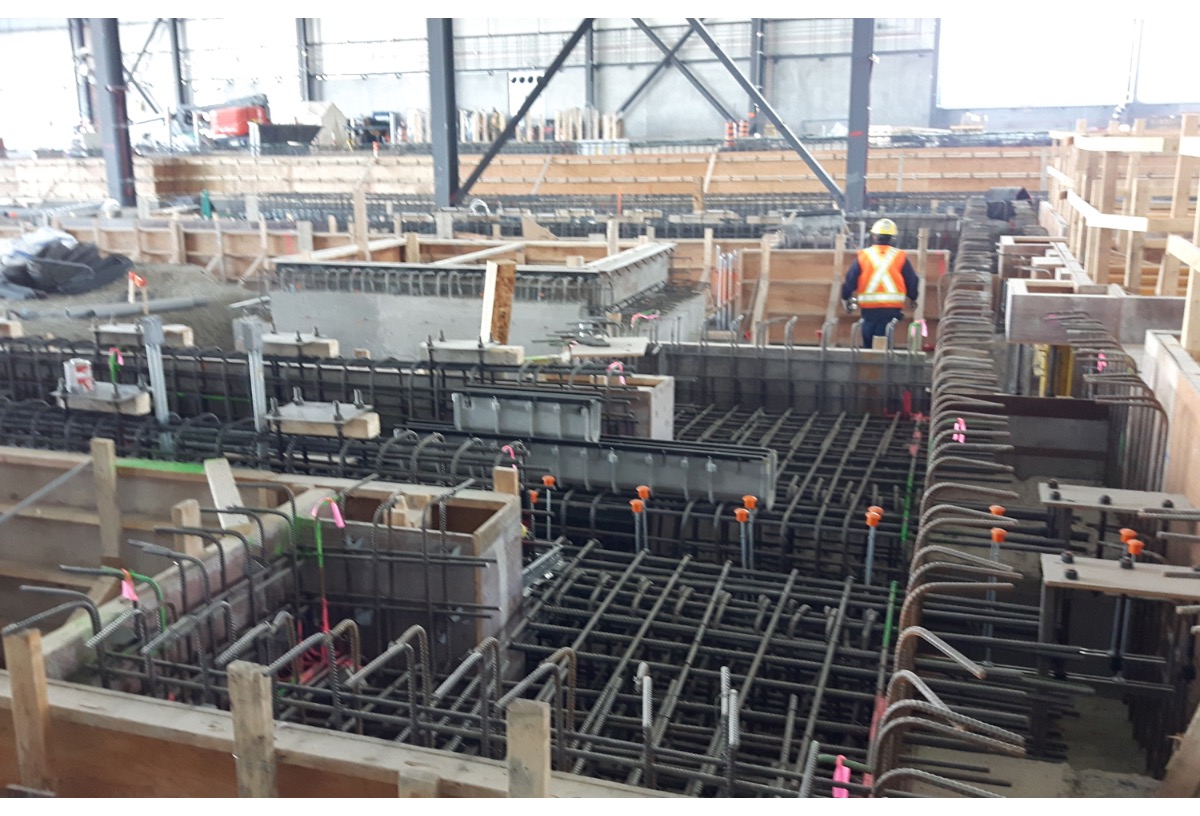

Repair in Place (RIP) jacks: Whiting Lifting Equipment

The Whiting Hydraulic RIP/One-Spot Lifting System can be engineered and arranged to maximise the efficiency of the lifting application at your repair facility. The hydraulic jacks are equipped with ratchet-type safety devices in addition to standard hydraulic safety devices.

Installation can provide side jacks for lifting both ends of the wagon simultaneously resulting in faster throughput. The use of this equipment also leads to increased wagon utilization as the workflow in end of wagon operations, such as changing out draft gear, is now completed in a shorter time period.

Hydraulic In-Floor Jack Installations Include:

65-tonne Outside Jacks at each side for lifting wagon, bolster, and side frame for repacking, removal of the bogie, and repair of under rolling stock members.

135-ton Centre Jack for jacking under the centre sill of special wagons, which cannot be handled with outside jacks. This allows roller bearing, axle, and wheel assemblies to be removed, permitting repacking, spring replacement, etc.

Operator Control Console so the operator does not need to be close to the freight wagon during the repair operation.

Features:

Remote control

Operator’s safety

Great lifting capacity

Body Hoists

Body Hoists: Whiting Lifting Equipment

Specific to light rail and trams, Whiting body hoists and supports can be used in conjunction with Whiting Passenger Rolling Stock Hoists to facilitate body and bogie separation, or to elevate rolling stock to safe heights and hold for inspections and repairs to the underbody.

Features:

Suitable for under the car inspection

Great power capacity

Variable raise height

Rail Bogie Repair Hoist

Bogie Repair Hoist: Whiting Lifting Equipment

A bogie repair hoist’s primary purpose is to increase shop safety and efficiency by providing maintenance personnel with a convenient access height for the inspection, maintenance and repair of the bogie.

Using a rugged and proven electro-mechanical steel-alloy screw and bronze-alloy nut design, the two-screw bogie repair hoists offers self-locking nuts along with steel safety nuts as backup for added failsafe protection. Added features like over travel limit switches help make the bogie repair hoists one of the safest pieces of equipment in your maintenance shop.

Whiting’s bogie repair hoists range in size from 8 to 20 tonnes and are an integral part of the car hoist maintenance system in many modern transit and freight maintenance shops. With minimal needed routine maintenance, Whiting bogie repair hoists are known for their long-term reliability, open design for easy bogie servicing and safety.

Features:

Highly safe and efficient

Minimal maintenance needed

Long-term reliability

Passenger Rolling Stock Hoists

Passenger Rolling Stock Hoists: Whiting Lifting Equipment

Whiting passenger rolling stock hoist systems are the safe solution when repairing light rail underbody and/or side components. Only Whiting hoists utilise a patented safety design to raise and lower rollingstock, reducing the possibility of incidents caused by sudden dropping of the elevated vehicle.

Passenger Rolling Stock Hoists raise the entire rolling stock body to a convenient height for worker access to underbody and side components. Utilising a time-tested mechanical screw and nut design, two or four screw designs are standard in capacity ranges up to 45 tonnes. Rolling stock can be raised individually, articulated, or in married pairs with hoists positioned under each bogie location.

Depending on your site needs, Whiting Passenger Rolling Stock Hoists can be custom engineered for deep or shallow pit configurations. An important feature of the electromechanical screw and nut design requires motor power to the Passenger Rolling Stock Hoists to both raise and lower, thus minimizing the possibility of inadvertent lowering of the hoist with personnel near the rollingstock.

Features:

Patented safety design

Variable raise height

Custom designs

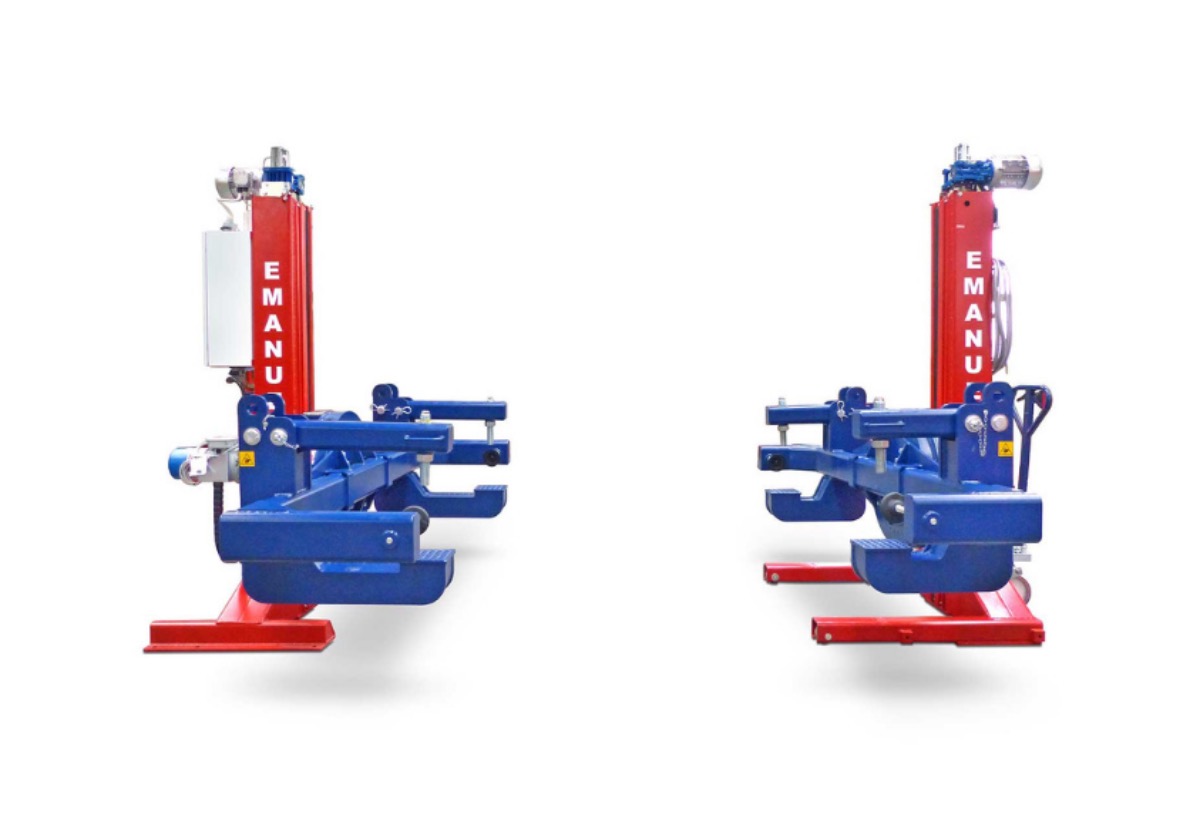

Lifting Bogie Platform

Lifting Bogie Platform: Emanuel Lifting Equipment

The CSF is a lifting bogie platform which runs on rails and allows for the handling, removal, and assembly of railway bogies during maintenance. The upper pad has a central opening which allows the operators to work safely under the lifted railway carriage.

The carriages support plane is made in compliance with the different track gauge systems – starting from a minimum of 1000 mm and up to a maximum of 1676 mm.

The lifting system can be controlled either through three-phase power supply or via a battery pack installed on the machine. In event of failure, a manual pump is installed to enable platform lifting and lowering.

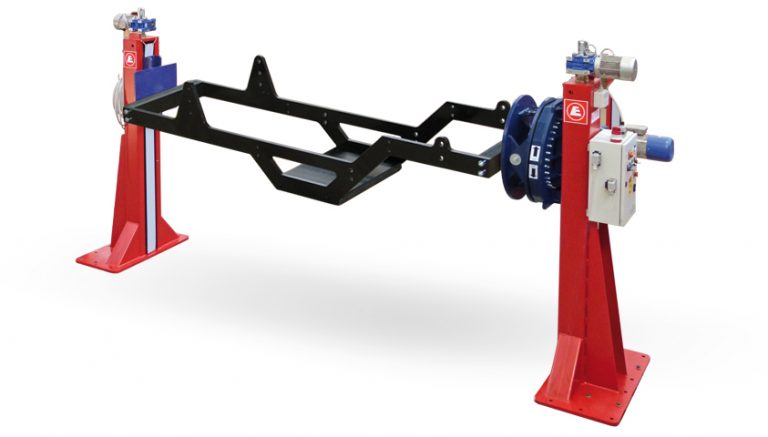

Dummy Bogies

Dummy Bogies: Emanuel Lifting Equipment

The CS is temporary railway bogie which runs on rails supporting rolling stock during bogie refurbishment.

Temporary bogies are also used for moving rolling stock during manufacturing processes, long term maintenance periods, as auxiliary elements in depots and track construction.

The carriages support plane is made in compliance with the different track gauge systems: starting from a minimum of 1000, 1435 mm and up to a maximum of 1676 mm.

Emanuel Rail Lifting Jacks

Emanuel Rail Lifting Jacks

Emanuel rail lifting jacks are flexible lifting options that can be custom designed to suit the application. Available in capacities between 5 and 50 tonne with fixed or movable anvil designs.

All Emanuel jacks are electromechanical design with lifting screw-nut system. They feature a load-bearing nut and safety nut, made from nylatron or bronze. All jacks come with an absolute encoder, with to a 12-bit processor directly connected to the lifting screw.

Emanuel offers three types of electronic control units:

- Standard: control up to 8 columns with expansion up to 16 with second control unit connected by a serial cable.

- Serial: control up to 28 columns.

- Portable controller: control up to 128 columns

Features:

Configurations from 4 to 128 columns

5 to 50 tonne capacity

Custom designed to suit application

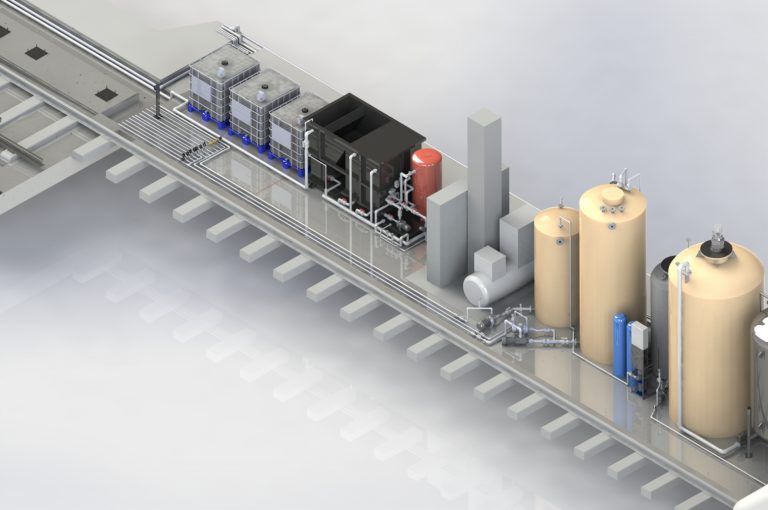

Rollingstock washing systems

Air Rail offers innovative an impressive range of Rollingstock Washing Systems and related components.

Air Rail can offer customised layouts and specialised washing plants, controlled via Air Rail’s engineering and manufacturing division.

Air Rail through partnership with Freightquip are able to individually analysing each customer’s requirements with the objective of delivering the most reliable, effective and environmentally friendly systems.

The product range includes;

- Assembled bogie washing systems

- Bogie washing cabins

- Drive through washing & blowing machines

- Dirty water extraction machines

- Mobile shuttle washing & blowing systems

- Train HVAC washing systems

- Water treatment plants

- Watertight checking systems

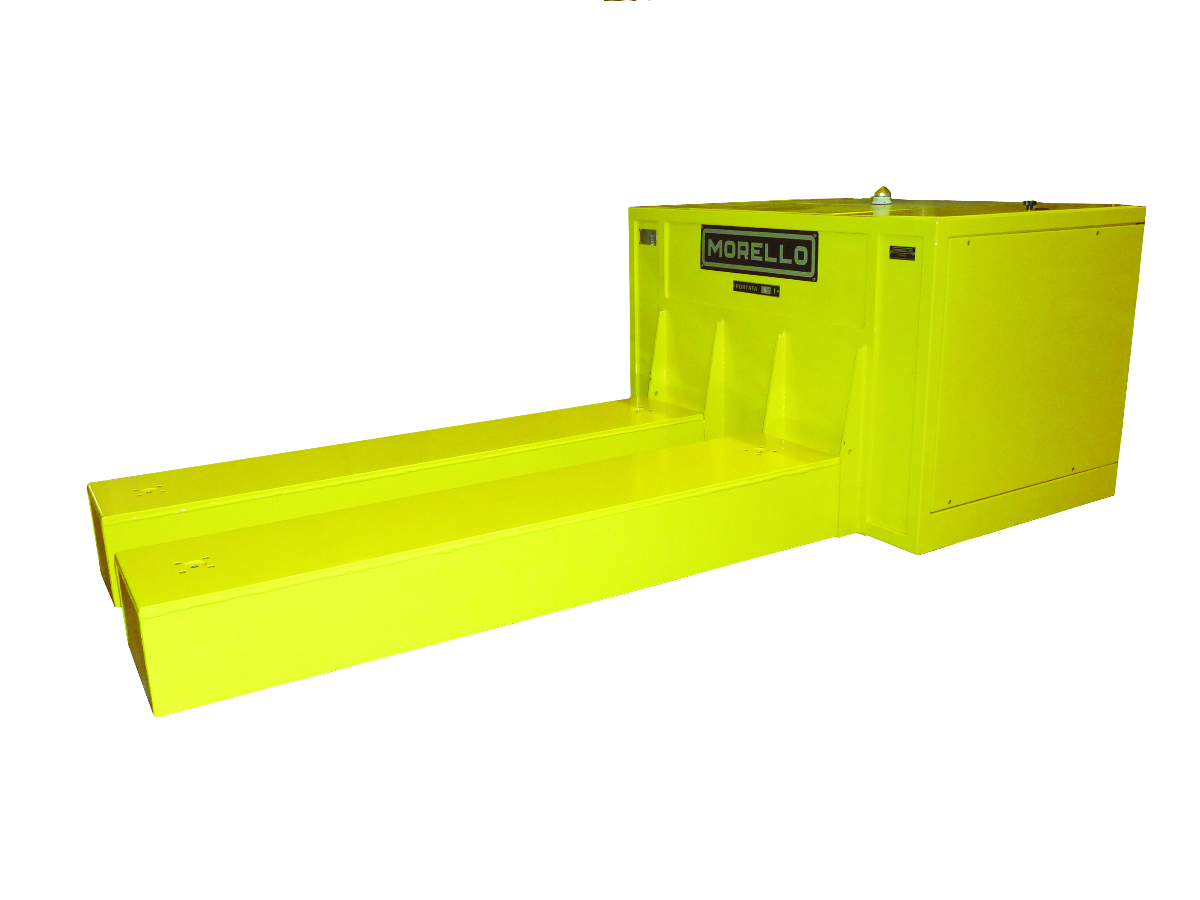

Battery Powered Trolleys OMNI

Morello Industrial Handling Vehicles

OMNI: Multidirectional steering battery powered trolleys.

Extended manoeuvring easiness is one of key features in OMNI heavy duty platform trolley offering maximum capacity of 1000 tones. Featuring a lifting deck on board (when necessary), this high-capacity quick change cart minimizes crane usage increasing productivity in the field while its extended versatility allows using this platform truck cart with any kind of load, on any type of floor even in narrowest spaces. OMNI flat deck transporter with omnidirectional steering will perfectly suit the widest range of payload and manoeuvrability needs in most restricted industrial spaces.

Further customization options including AGV version are made for particular operational conditions such as: explosion-proof platform truck carts for hazardous areas, painting rooms, as well as field application in oil-and-gas and mining industries.

Features:

Customisable design that can be tailored to suit the application

Range of steering modes for superior manoeuvrability

Local support available

Battery Powered Trolleys SGAI

Morello Industrial Handling Vehicles

SGAI: Normal steering battery powered trolleys.

Based on wheels with normal steering, Morello’s motorised platform truck SGAI is designed to bring the heavy loads where overhead cranes cannot operate ensuring precise movement in limited places with strictly constrained paths. SGAI platform truck carts have no predefined path with an opportunity to steer and move on any kind of floor.

Further customization options including AGV version are made for particular operational conditions such as: explosion-proof platform truck carts for hazardous areas, painting rooms, as well as field application in oil-and-gas and mining industries.

Features:

Customisable design that can be tailored to suit the application

Range of steering modes for superior manoeuvrability

Local support available

Automated Guided Vehicles

Morello Industrial Handling Vehicles

Morello designs and manufactures automated guided carts AGV tailored to suit specific customer requirements in a variety of industrial sectors. Heavy-load AGV cart are available with capacity from 2 up to 1,000 tons.

AGV can operate in complete autonomy without operator or any physical guidance which results in:

- Reduction of operational costs

- Advanced security

- Increased accuracy and productivity

- Reduction of damage to products and work environment

- Possibility of working in dangerous or hostile environment (for example explosive environment)

A range of different navigation options are available including:

- Inductive Guidance

- Inertial Guidance

- Magnetic Guidance

- Optical Guidance

- Laser Guidance

- GPS Guidance

Features:

Customisable design that can be tailored to suit the application

Range of steering modes for superior manoeuvrability

Local support available

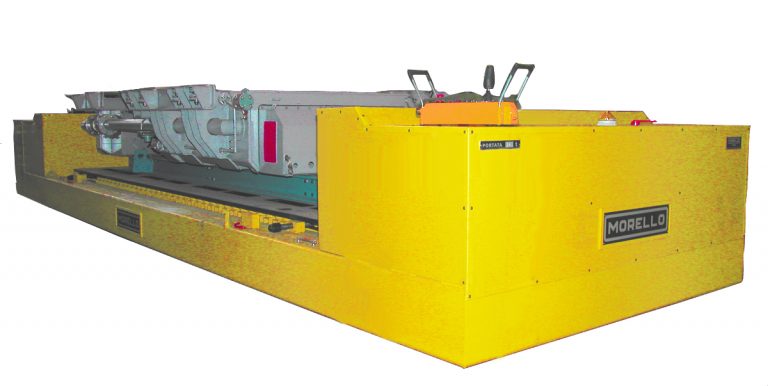

Rail Guided Powered Trolleys

Morello Industrial Handling Vehicles

Morello offers modern rail transfer cart for a range of different industry applications;

- Coil handling steel industry,

- Concrete manufacturing,

- Transportation in factories,

- Warehouses,

- Ports,

- And the variety of hard duty fields where moving on rails is required and production cycles are regular both timewise and route-wise.

As they are equipped with rail wheels that move on track, they are suited to very high loading capacities thanks to the low friction coefficient. The cost of these transfer trolleys – compared with the equivalent battery and diesel-powered trolleys on wheels – is much lower since these units do not require steering systems and use capacity powertrains.

Morello, with its 70 years of experience in rail transfer cart production, has a strong focus towards design and innovation offers and offers vehicles that use the latest technology.

Features:

Complete customization in every aspect of self-propelled system (dimensions, speed, capacity, etc.)

Compliance with Local and International Standards

Local support available

Self-Propelled Trailers

Morello Industrial Handling Vehicles

Self-propelled trailers are used to handle any type of load, oversized and heavy, even in presence of limited spaces.

The trailers are designed based on the customer requirements, with a range of options available.

- Electronic steering systems

- Diesel or Electric powered

- Hydraulic compensation of axles if ground slopes are uneven

- Mechanical coupling or electronic coupling of multiple trailers to allow for oversized or heavy loads.

- Automatic movement (AGV)

Features:

Complete customization in every aspect of self-propelled system (dimensions, speed, capacity, etc.)

Compliance with Local and International Standards

Local support available

Industrial Trailers

Morello Industrial Handling Vehicles

The Morello Industrial trailer is designed to handle a wide range of loads, even if in presence of limited spaces.

The trailers are designed based on the customer requirements, with a range of options available, for example:

- A series of steering trailers are available with centre-corrected vault, to minimize curvature radius for limited space applications.

- Telescopic supports are available to handle loads with a high centre of gravity, or unevenly distributed.

- Equipped with super-elastic or pneumatic tyres to handle un-even flooring.

- Steel plate, wooden or open loading platform depending on the application

- Fixed or moveable coverings

Features:

Customisable design that can be tailored to suit the application

Range of steering modes for superior manoeuvrability

Local support available

IECEx / ATEX Trolleys for Hazardous Environment

Morello Industrial Handling Vehicles

Morello design and manufactures IECEx / ATEX powered trolleys and towed trailers for use within the Oil & Gas industry, chemical industry, mines, painting rooms and any other environment where explosion proof trolleys are needed.

To handle equipment in these hazardous areas customized and certified explosion proof transporters are necessary.

Each IECEx and ATEX power deck is equipped with explosion proof components, certified depending on different hazardous areas (Zone 1&2, gas and dust).

If requested they can also be supplied with various notify body certifications: ATEX and IECEx third part certifications, lifting tools certifications, factory test certifications

Due to the adverse conditions in which these transfer cars have to operate they are waterproof, with electrical components protection up to IP 69.

Features:

Complete customization in every aspect of self-propelled system (dimensions, speed, capacity, etc.)

Compliance with Local and International Standards

Local support available

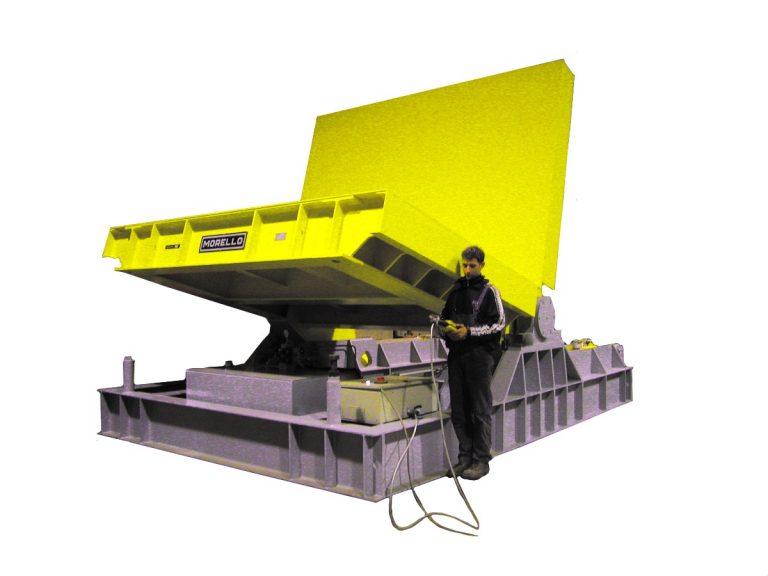

Upenders / Tilters

Morello Industrial Handling Vehicles

Upender or Tilter is widely used all over the world providing modern demanding industries with enhanced productivity and extreme safety during 90-, 180- and 360-degree tilting of large and very heavy materials.

A dedicated machine for upending allows an operator to unload overhead cranes. Upender is completely safe since it avoids holding the load raised during tilting, in this way saving operators from difficult and dangerous manoeuvers. Morello supplies flat deck upender for mold, dies, coils, castings, and other material handling in a variety of manufacturing industries all over the world.

Morello upenders can be customized according to special needs: payload, loading decks size and covers, tilting speed and other options can be studied together with the client.

Features:

Safe operating procedures

Customisable to suit the workflow

Local support available

Ergonomic Positioners

Emanuel offer a range of ergonomic positioners that allow lifting and rotation of any kind of frame.

The Emanuel positioners offer many advantages:

- Improved production quality by working at the ideal height and position preferred.

- Increased productivity due to lifting and turning products without overhead cranes or ordinary cranes.

- Improved worker health and safety as the need is reduced for dangerous movements of products with overhead cranes or ordinary cranes and the workers maintain an optimum posture.

Can be used for a variety of applications including; Overhauling and servicing train bogies, construction of frames for lorries, military vehicles, agricultural and railway machines, components for earth moving machines, and much more.

Features:

Movements can be programmed and stored using a PLC

Easy to use

Local product support available

DANOBAT Solutions

DANOBAT are specialists in advanced solutions for the manufacture of high value-added components in the most demanding industrial sectors.

DANOBAT have solid experience in advanced machining processes, and have designed customised solutions adapted to the customers specific requirements. These solutions range from preliminary engineering work, studies of machining processes, production simulation studies, technical specifications of the equipment, requirements of facilities and the human resources required to operate the production line.

DANOBAT and Freightquip provide fully automated solutions that integrate manufacturing and inspection equipment with robotised part handling systems, managed by our own control system.

As soon as the system is in operation, we supply our own equipment and processes monitoring infrastructure that perform a diagnosis in case of errors, preventive maintenance of the equipment and continuous optimization of machine operation and machining process conditions.

Steps

Idea: A collaborative and client focused approach to define the draft project that is most suitable to your particular requirements.

Design: Design the manufacturing process and the necessary equipment.

Performance: Take charge of the manufacture and supply of equipment.

Setting: Responsible for the installation and commissioning.

Operation: Guarantee an optimal performance of the solution.

Features:

Delivery of complete end-to-end solutions

Completely automatized solutions

Local support available

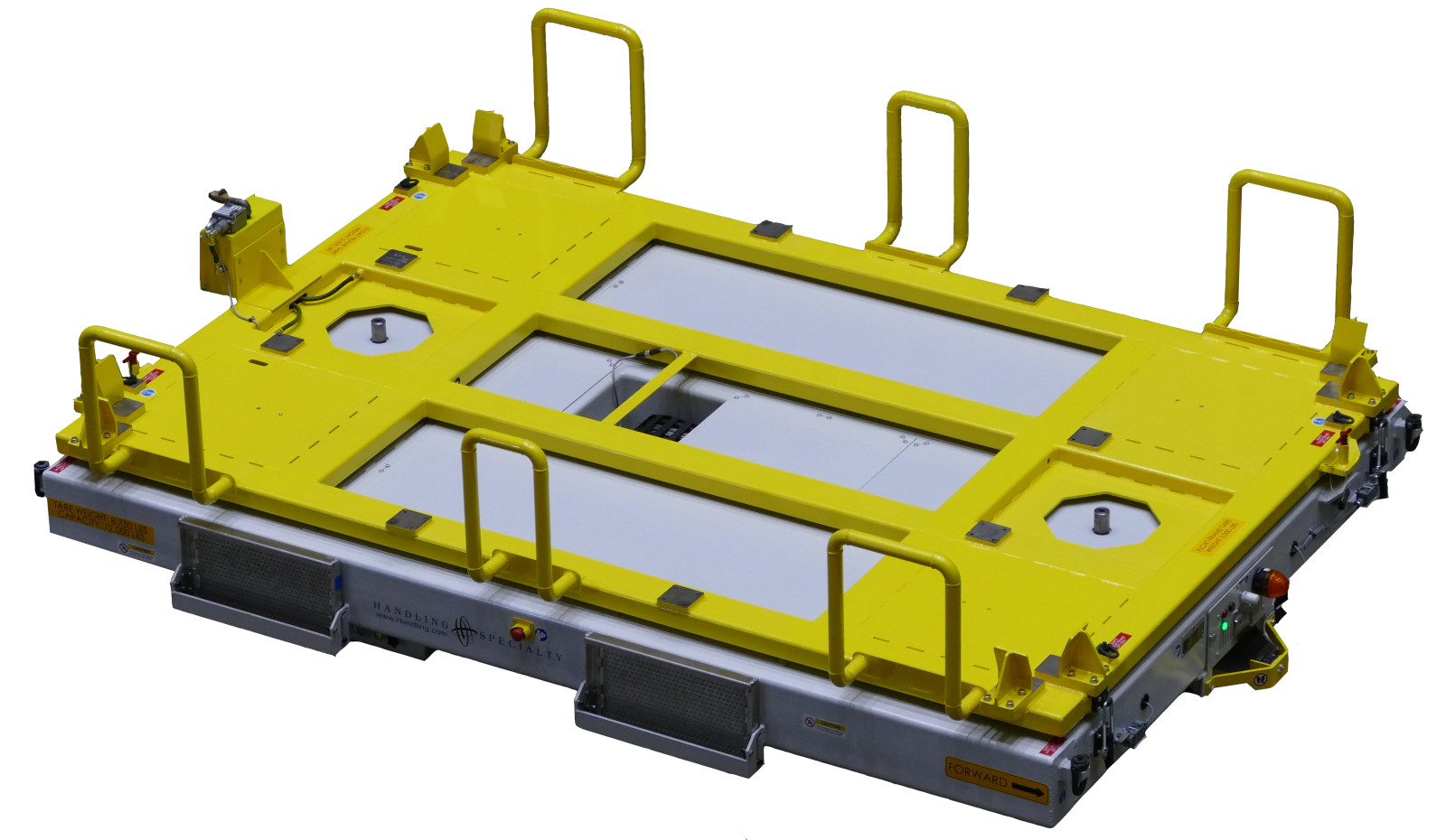

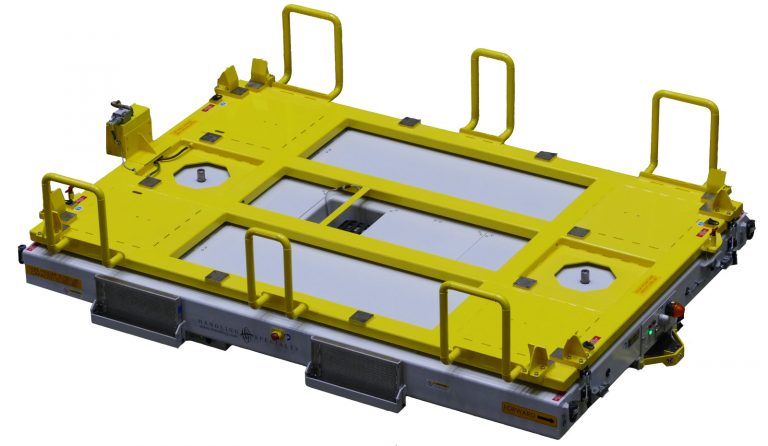

Handling Specialty

Handling Specialty are true specialists at providing turnkey solutions. They offer a one-stop shop for the design, manufacture, and installation and support on major projects. They are a premier source of made to order lifting, tilting, rotating and traversing requirements that can be designed, engineered and installed as a turnkey solution.

Design capabilities coupled with engineering expertise allow Handling Specialty to handle one of a kind applications that may have unique or extreme requirements.

Features:

Delivery of complete end-to-end solutions

From part automation through to full automation

Local support available

Whiting Lifting Jacks

Whiting Rail Lifting Jacks

The outstanding design and quality construction of Whiting Portable Electric Jacks provide years of dependable service with a minimum of maintenance.

All Whiting Jacks start with a welded steel base and structural steel column. Connected to this frame, the alloy steel jack screw is keyed to a worm gear supported by a large thrust bearing.

The jack screw uses precision-machined buttress threads. In this application, Buttress threads are more efficient and safer than other threads. The aluminium bronze nut travels on the screw and supports the welded steel lifting bracket.

The jacks are easy to manoeuvre, providing ability to easily perform maintenance work at any location and at any time within your facility. Specialised anvil designs allow for complete customization to ensure an exact match to your rolling stock.

From a master control station mounted to a dedicated jack, an operator can simultaneously engage a set of jacks. Each jack is additionally equipped with push button controls for individual operation.

Features

Sealed bellows offers superior dust and debris protection

- Sealed bellows offers superior dust and debris protection

- Alloy steel jack screw readily accessible for easy inspection and fast maintenance

- Bronze alloy lifting nut designed for long life with proper maintenance

- Self-locking fail-safe jack screws won’t drop load in case of power loss

Features:

Tough construction

Buttress threads

Interlocking Controls

Single Axle Drop Tables

For individual wheelset change-out the Whiting single-axle drop table enables fast, easy and efficient operations. With hoisting capacity up to 60t it can accommodate heavy wheelset and traction motor combinations.

Whiting understands the demands of modern railcar maintenance shops. Built to the highest quality standards, Whiting single-axe drop tables continue to run in the harshest conditions. With flexible design options and an experienced engineering team, Whiting designs each drop table to meet the unique application requirements of your facility with a focus on long-term reliability and ease of maintenance. drop tables are assembled, and load tested before delivery to make sure all performance specifications are met.

Features:

Semi or fully automatic

Maxim lift strength

Long service life

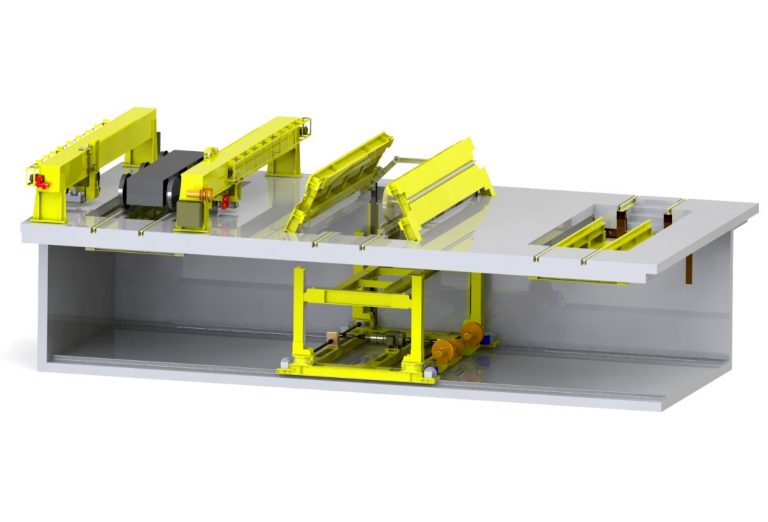

Bogie Drop Tables

Whiting Lifting Equipment

Whiting pioneered the development of the drop table concept. Bogie and wheelset change outs are fast, easy, and efficient using a Whiting drop table. Whiting engineers take the time to listen and create a drop table system that fits your application. Like all Whiting Railcar Maintenance Equipment, all our bogie drop tables are built with reliability, safety, and ease of maintenance in mind.

Bogie drop tables are used to change out two and three axle bogies up to 250 tons. To remove drive wheels or bogies with a bogie drop table, the locomotive is located and supported over the tabletop, where the bogies (or wheelsets) are disconnected, lowered, transferred laterally and then raised to a release track. The bogies can then be moved to a maintenance area where inspection and repair can be performed quickly and efficiently.

Features:

Remote controlled

Able to change out 2-3 wheel axle trucks

Fully automatized

Rail Traversers

Traversers (or transfer tables) are an invaluable tool for maintaining traffic flow between rail tracks in your car repair or maintenance shop.

Traversers can be installed with pit or without pit, completely automatic or with a semi-automatic control.

Movement of vehicles on and off the traverser can also be managed by winches or a progression system supplied on the transfer table.

Small diameter turntables used for rotating bogies are designed with a large centre slewing bearing. Therefore, the bearing can withstand large cantilever forces; additional sets of support wheels near the outside diameter of the turntable is not required. This design also simplifies the installation because the additional pit track for the support wheels is not required. Furthermore, the slewing bearing allows for an easy manual rotation of the turntables by an operator.

Features:

No pit required

Indispensable in any maintenance shop

Local support available

Rollingstock Turntables

Whiting Rail Turntables are custom-engineered and manufactured in different sizes based upon the application. Whiting Turntables are extremely rugged, well-balanced, and are suitable for the heavy demands of rail maintenance shops.

Locomotive Turntables reduce the need for extended track turnabouts, and are motorized with a remote operator station for safe and easy use. Whiting Turntables utilize both centre bearing and caster designs depending on your application.

Features:

Long term reliability and safety

Easy of use and maintain

Local support available

Underfloor Wheel Lathe

Each DANOBAT Underfloor Wheel Lathe allows this essential maintenance to be done without the need to dismount the train axle. Single or tandem machines are available with user-friendly, intuitive software. The equipment can be adapted to suit the required gauge width. The DANOBAT Underfloor Wheel Lathe features a continuous measurement of the wheel profile and a fully automatic machining processes for perfect results.

DANOBAT offers a complete solution including the underfloor wheel lathe, wheelset optimisation software and wheel profile measuring equipment.

Features:

Fully automatic machining processes

Optimised wheelset life

Local factory-trained support available

Depot Control System

Offering a cost-effective alternative to the current Locally Operated Points System (LOPS) or depot points control system, the FirstClass Safety & Control Depot Control System has been designed to suit any rail depot* where safety is key for train or rollingstock movements.

The FirstClass Safety & Control Depot Control System uses industry-proven aspects, route indicators, points machines, train detection methods and has SIL2 safety-rated PLC hardware/software. It is also a bespoke design solution that has been designed for easy integration.

*Working with approved rail signalling contractors

Features:

Cost-effective alternative to mainline signaling systems

SIL2 safety rated

Local support available

Depot Protection System

The FirstClass Safety & Control Depot Protection System is an integrated safety control system that is individually designed for any rail depot looking for a new system or to upgrade.

This bespoke, ease to integrate Depot Protection System uses proven off-the-shelf hardware and software which comes highly recommended within the rail industry. The entire system is built to be flexible, scalable and reliable.

It is also an incredibly cost-effective and safe solution with a SIL2 safety rating.

FirstClass Safety & Control are proud to be a RISQS approved and ISO 9001 & 45001 accredited company in the UK.

Features:

Flexibility to tailor systems to meet specific site requirements

Can be integrated with 3rd systems

Local support available

Rail Portal Lathe

Danobat Wheel Shop Equipment

The DANOBAT DPL Portal Lathe has been expertly designed and manufactured to handle railway locomotive, wagon and coach wheelset maintenance applications. The CNC machine is a portal type, designed and configured to allow machining and measuring under high static and dynamic loads. Like all the DANOBAT range, the DPL Portal Lathe is designed to help you deliver excellence.

Features:

High production throughout

Impressive material removal capacity

Rigid with excellent damping properties.

Hercules

Trackmobile Diesel Shunt Vehicle

A mid-range capacity model, the Hercules is the market’s most popular class of machine to date. Designed with floating axles, to ensure 4 points of contact on the rail at all times and an ergonomically designed cab to provide operator comfort, the Hercules can be ordered with two model exclusive option packages; a ballasted frame or a Wide Cab option, noting the wide cabin makes the unit more streamlined to allow it fit between elevated platforms in locomotive and wagon rollingstock maintenance facilities. These models of rail shunting equipment are currently utilised at locations within Australia as shunt and vehicle placers, locomotive shunting and in lieu of progression systems.

Features:

Most popular model in the market. Available in standard or wide cabin alternatives.

Ergonomics, safety and operator comfort

Versatile

Titan

Trackmobile Diesel Shunt Vehicle

Introduced in 2006, the Titan was designed for applications with higher duty cycle requirements. It is engineered to conquer challenging rail conditions while an ergonomically designed cab offers enhanced operator comfort. Titan’s split pivoting mainframe is linked by an oscillating bearing that pivots up to 10° to assure 4-wheel rail contact at all times and extends axle life. For a 15% tractive effort boost, the Titan can also be ordered with the AD-TRACTM option. These models of rail shunting equipment are currently utilised at locations within Australia as shunt and vehicle placers, locomotive shunting and in lieu of progression systems.

Features:

Good performance in bad rail conditions

Ergonomics, safety and operator comfort

Extended axle life due to oscillating bearing

Viking

Trackmobile Diesel Shunt Vehicle

The Viking is Trackmobile’s most nimble capacity model. Perfect for lower duty cycle applications where reliability is critical, Viking quickly gets the job done safely and efficiently. Equipped with many of the same features as the Hercules, Viking operators enjoy the same dependable performance and ergonomically designed cab to ensure operator comfort. These models of rail shunting equipment are currently utilised at locations within Australia as shunt and vehicle placers, locomotive shunting and in lieu of progression systems.

Features:

Most nimble model

Quick, safe & efficient

Ergonomic & operator comfort

Atlas

Trackmobile Diesel Shunt Vehicle

The Atlas is Trackmobile’s highest capacity model. Designed for more rugged and higher duty cycle applications, the Atlas is optimized to handle the most severe rail conditions with optimal operator comfort. As the premier model, the Atlas offers many options as standard features. These models of rail shunting equipment are currently utilised at locations within Australia as shunt and vehicle placers, locomotive shunting and in lieu of progression systems.

Features:

Highest capacity

Good performance in bad rail conditions

Ergonomics, safety and operator comfort