Lifting Equipment

Body Supports

Body Supports: Whiting Lifting Equipment

Used in conjunction with Whiting body hoists, Whiting body supports have no motive power capability to raise and lower cars but provide support of the rolling stock body when bogies are being removed. Standard capacities range from 4.5 to 18 tonnes.

Features:

Suitable for under the car inspections

Great power capacity

Variable raise height

Repair in Place (RIP) Jacks

Repair in Place (RIP) jacks: Whiting Lifting Equipment

The Whiting Hydraulic RIP/One-Spot Lifting System can be engineered and arranged to maximise the efficiency of the lifting application at your repair facility. The hydraulic jacks are equipped with ratchet-type safety devices in addition to standard hydraulic safety devices.

Installation can provide side jacks for lifting both ends of the wagon simultaneously resulting in faster throughput. The use of this equipment also leads to increased wagon utilization as the workflow in end of wagon operations, such as changing out draft gear, is now completed in a shorter time period.

Hydraulic In-Floor Jack Installations Include:

65-tonne Outside Jacks at each side for lifting wagon, bolster, and side frame for repacking, removal of the bogie, and repair of under rolling stock members.

135-ton Centre Jack for jacking under the centre sill of special wagons, which cannot be handled with outside jacks. This allows roller bearing, axle, and wheel assemblies to be removed, permitting repacking, spring replacement, etc.

Operator Control Console so the operator does not need to be close to the freight wagon during the repair operation.

Features:

Remote control

Operator’s safety

Great lifting capacity

Body Hoists

Body Hoists: Whiting Lifting Equipment

Specific to light rail and trams, Whiting body hoists and supports can be used in conjunction with Whiting Passenger Rolling Stock Hoists to facilitate body and bogie separation, or to elevate rolling stock to safe heights and hold for inspections and repairs to the underbody.

Features:

Suitable for under the car inspection

Great power capacity

Variable raise height

Rail Bogie Repair Hoist

Bogie Repair Hoist: Whiting Lifting Equipment

A bogie repair hoist’s primary purpose is to increase shop safety and efficiency by providing maintenance personnel with a convenient access height for the inspection, maintenance and repair of the bogie.

Using a rugged and proven electro-mechanical steel-alloy screw and bronze-alloy nut design, the two-screw bogie repair hoists offers self-locking nuts along with steel safety nuts as backup for added failsafe protection. Added features like over travel limit switches help make the bogie repair hoists one of the safest pieces of equipment in your maintenance shop.

Whiting’s bogie repair hoists range in size from 8 to 20 tonnes and are an integral part of the car hoist maintenance system in many modern transit and freight maintenance shops. With minimal needed routine maintenance, Whiting bogie repair hoists are known for their long-term reliability, open design for easy bogie servicing and safety.

Features:

Highly safe and efficient

Minimal maintenance needed

Long-term reliability

Passenger Rolling Stock Hoists

Passenger Rolling Stock Hoists: Whiting Lifting Equipment

Whiting passenger rolling stock hoist systems are the safe solution when repairing light rail underbody and/or side components. Only Whiting hoists utilise a patented safety design to raise and lower rollingstock, reducing the possibility of incidents caused by sudden dropping of the elevated vehicle.

Passenger Rolling Stock Hoists raise the entire rolling stock body to a convenient height for worker access to underbody and side components. Utilising a time-tested mechanical screw and nut design, two or four screw designs are standard in capacity ranges up to 45 tonnes. Rolling stock can be raised individually, articulated, or in married pairs with hoists positioned under each bogie location.

Depending on your site needs, Whiting Passenger Rolling Stock Hoists can be custom engineered for deep or shallow pit configurations. An important feature of the electromechanical screw and nut design requires motor power to the Passenger Rolling Stock Hoists to both raise and lower, thus minimizing the possibility of inadvertent lowering of the hoist with personnel near the rollingstock.

Features:

Patented safety design

Variable raise height

Custom designs

Lifting Bogie Platform

Lifting Bogie Platform: Emanuel Lifting Equipment

The CSF is a lifting bogie platform which runs on rails and allows for the handling, removal, and assembly of railway bogies during maintenance. The upper pad has a central opening which allows the operators to work safely under the lifted railway carriage.

The carriages support plane is made in compliance with the different track gauge systems – starting from a minimum of 1000 mm and up to a maximum of 1676 mm.

The lifting system can be controlled either through three-phase power supply or via a battery pack installed on the machine. In event of failure, a manual pump is installed to enable platform lifting and lowering.

Dummy Bogies

Dummy Bogies: Emanuel Lifting Equipment

The CS is temporary railway bogie which runs on rails supporting rolling stock during bogie refurbishment.

Temporary bogies are also used for moving rolling stock during manufacturing processes, long term maintenance periods, as auxiliary elements in depots and track construction.

The carriages support plane is made in compliance with the different track gauge systems: starting from a minimum of 1000, 1435 mm and up to a maximum of 1676 mm.

Emanuel Rail Lifting Jacks

Emanuel Rail Lifting Jacks

Emanuel rail lifting jacks are flexible lifting options that can be custom designed to suit the application. Available in capacities between 5 and 50 tonne with fixed or movable anvil designs.

All Emanuel jacks are electromechanical design with lifting screw-nut system. They feature a load-bearing nut and safety nut, made from nylatron or bronze. All jacks come with an absolute encoder, with to a 12-bit processor directly connected to the lifting screw.

Emanuel offers three types of electronic control units:

- Standard: control up to 8 columns with expansion up to 16 with second control unit connected by a serial cable.

- Serial: control up to 28 columns.

- Portable controller: control up to 128 columns

Features:

Configurations from 4 to 128 columns

5 to 50 tonne capacity

Custom designed to suit application

Whiting Lifting Jacks

Whiting Rail Lifting Jacks

The outstanding design and quality construction of Whiting Portable Electric Jacks provide years of dependable service with a minimum of maintenance.

All Whiting Jacks start with a welded steel base and structural steel column. Connected to this frame, the alloy steel jack screw is keyed to a worm gear supported by a large thrust bearing.

The jack screw uses precision-machined buttress threads. In this application, Buttress threads are more efficient and safer than other threads. The aluminium bronze nut travels on the screw and supports the welded steel lifting bracket.

The jacks are easy to manoeuvre, providing ability to easily perform maintenance work at any location and at any time within your facility. Specialised anvil designs allow for complete customization to ensure an exact match to your rolling stock.

From a master control station mounted to a dedicated jack, an operator can simultaneously engage a set of jacks. Each jack is additionally equipped with push button controls for individual operation.

Features

Sealed bellows offers superior dust and debris protection

- Sealed bellows offers superior dust and debris protection

- Alloy steel jack screw readily accessible for easy inspection and fast maintenance

- Bronze alloy lifting nut designed for long life with proper maintenance

- Self-locking fail-safe jack screws won’t drop load in case of power loss

Features:

Tough construction

Buttress threads

Interlocking Controls

Single Axle Drop Tables

For individual wheelset change-out the Whiting single-axle drop table enables fast, easy and efficient operations. With hoisting capacity up to 60t it can accommodate heavy wheelset and traction motor combinations.

Whiting understands the demands of modern railcar maintenance shops. Built to the highest quality standards, Whiting single-axe drop tables continue to run in the harshest conditions. With flexible design options and an experienced engineering team, Whiting designs each drop table to meet the unique application requirements of your facility with a focus on long-term reliability and ease of maintenance. drop tables are assembled, and load tested before delivery to make sure all performance specifications are met.

Features:

Semi or fully automatic

Maxim lift strength

Long service life

Bogie Drop Tables

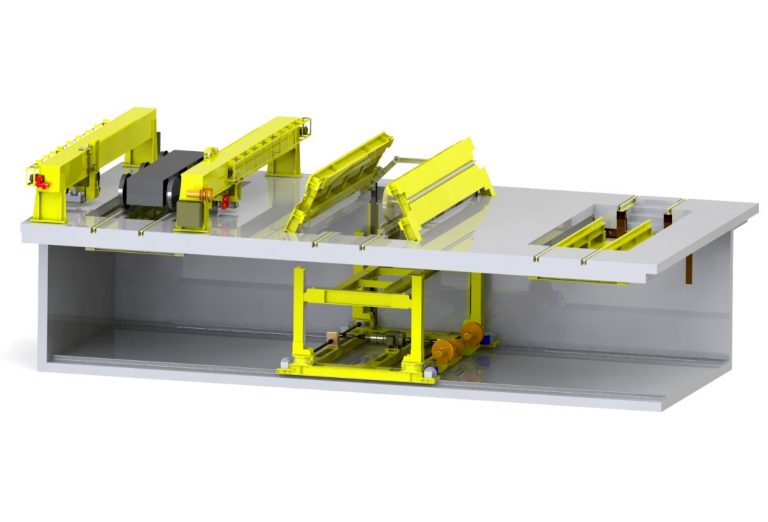

Whiting Lifting Equipment

Whiting pioneered the development of the drop table concept. Bogie and wheelset change outs are fast, easy, and efficient using a Whiting drop table. Whiting engineers take the time to listen and create a drop table system that fits your application. Like all Whiting Railcar Maintenance Equipment, all our bogie drop tables are built with reliability, safety, and ease of maintenance in mind.

Bogie drop tables are used to change out two and three axle bogies up to 250 tons. To remove drive wheels or bogies with a bogie drop table, the locomotive is located and supported over the tabletop, where the bogies (or wheelsets) are disconnected, lowered, transferred laterally and then raised to a release track. The bogies can then be moved to a maintenance area where inspection and repair can be performed quickly and efficiently.

Features:

Remote controlled

Able to change out 2-3 wheel axle trucks

Fully automatized